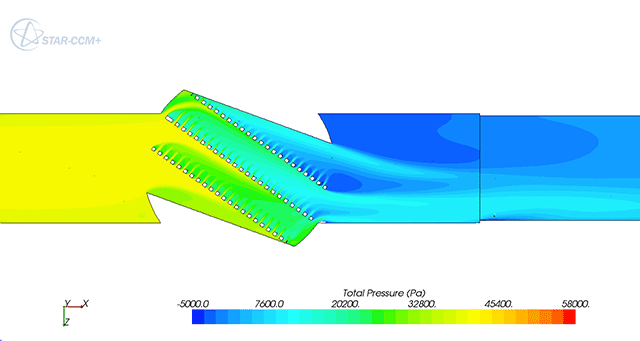

DAFRAM multi-stage ball valves are equipped with an internal cage that splits the pressure drop into several stages. Each stage is made up of a drilled plate placed in the ball hole. The number and configuration of internal stages are defined to meet the working conditions specified by the customer, in order to ensure the best flow control capability.

Multi-stage ball valves are designed to operate against high pressure drops providing excellent control capability and noise attenuation during a long service life. Furthermore, thanks to DAFRAM proven experience, tight shut-off and zero external leakage are a fixed point.

Compared to a standard ball valve, which is actually a two-stage valve, the multi-stage solutions ensures a very low pressure recovery factor, hence reducing flow velocity, ice formation and the risk of cavitation. The pressure energy is smoothly dissipated through the stages.

TECHNICAL DATA

- Design standards: DAFRAM control ball valves are in compliance with IEC 60534; other international standards or customer specifications are available on request.

- Materials: it is possible to choose over a wide range of materials to meet the process conditions.

- Hard facing: to ensure a long service life many different coatings are available to prevent ball and seats from damage due to erosive flow and continuous operation.

- Actuating: customer can choose between pneumatic (double acting or spring return), electric or hydraulic actuators; main actuators manufacturers are in collaboration with DAFRAM to ensure the best service.

- Positioning: many manufacturers can provide pneumatic & digital positioners to meet customers request.

MAIN ADVANTAGES

- Less expensive than a same Cv globe valve: for a given Cv a rotary valve is much smaller than a globe valve, thus ensuring less weight, smaller actuators and piping stress minimization.

- Cavitation control: dividing the pressure drop into several stages reduces the pressure recovery factor, so the vena contracta pressure is maintained over the vapour pressure limit.

- Noise control: a low recovery factor reduces also the maximum speed inside the valve, ensuring a lower sound pressure level and vibration reduction related to the stages configuration.

- High flow coefficient: in the fully open position the plates offer a minimum resistance to the flow so the Cv is very high compared to other control valve types.

- Bi-directional valve and symmetric trim: the valve design allows to control flow in both directions; moreover, the ball is symmetric so there are no limitations for plant installation.